|

Strong points: |

Application: |

Size Range |

Note: |

|

1. 23% lighter than steel ball, which means less centrifugal force and less friction on the groove during high speed and acceleration. |

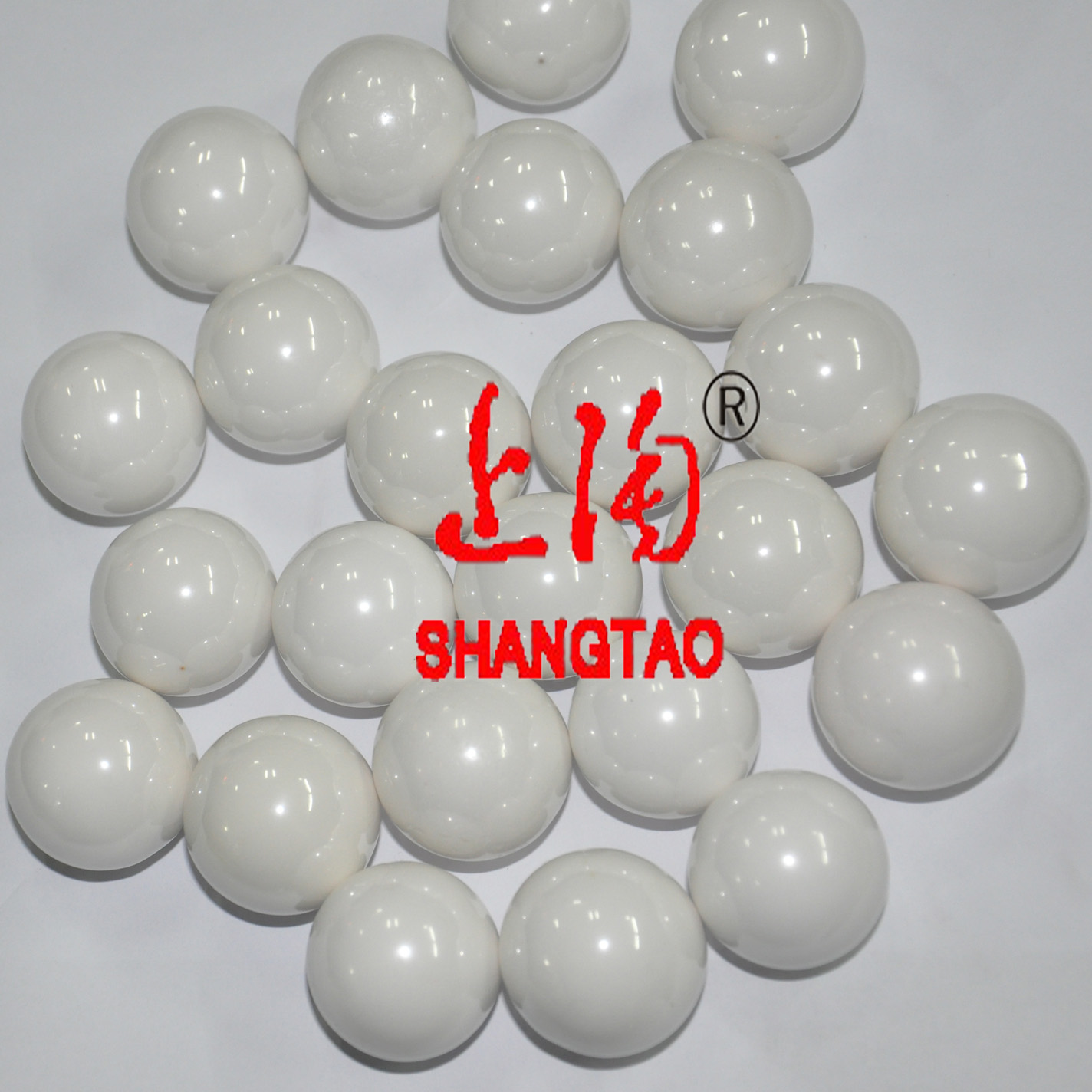

ZrO2 ball is mainly used for valve ball, full ceramic bearing, metering ball, track ball, and precision grinding ball; it can be used in fields requiring chemical resistance, high temperature,electronic insulation,magnetic insulation, non-lubrication. ZrO2 ball is an idea substitute for steel ball in chemical corrosion application. As valve ball, ZrO2 ball is now successfully used in high pressure homogenizer, diaphragm pump, metering pump, oil well pump, high pressure sprayer etc |

0.4mm~50.8mm (1/64”~2”) with different gauge |

1) white color as standard, yellow ZrO2 ball could be supplied upon customer requirement. 2) plenty of stock. 3) non-standard size could be supplied. 4) thermal expansion coefficient of ZrO2 is 10.5*10-6/°C, similar to that of steel, which means ZrO2 has well fitting with metal. However, it also results in larger size change with temperature fluctuation. Also, ZrO2 fractures in rolling-failure, thus it is less stable than Si3N4 in key application. |

|

2. Smaller friction coefficient, more freely rolling. | |||

|

3. Can be used at higher temperature up to 750ºC. | |||

|

4. Never rust, and can roll without lubrication. | |||

|

5. More corrosion resistant than steel | |||

|

6. No metal contamination. | |||

|

7. Non-magnetic. | |||

|

8. Electric isolation. |

It have high strength and tenacity,good wear-resistance,high temperature and corrosion resistance,high rigidity,no-magnetism and electric insulation under normal temperature.When temperature at 600 C,the strength and hardness of zirconia ceramic ball is almost unchanged.Density:6.00g/cm3,the thermal expansion is close to metal’s.It can be used with metal together.Used for bearing,sealing parts ect.High purity zirconia beads is the most ideal grinding media at present.Widely applied in grinding and dispersing of material in non-metal mine,dope,printing pink,paint,dye, titanium pigment,pesticide,magnetic material ect industry.

Main technic parameter:

|

Content of ZrO2 |

True density |

Low bulk density |

Flexural strength |

Crushing tenacity |

Hardness(HRA) |

|

97% |

|

3.7g/cm3 |

≥1000Mpa |

12-14Mpa |

≥90 |

Specification (mm):

φ0.5-0.8 0.8-1.0 1.0-1.2 1.2-1.4 1.4-1.6 1.6-2.0 2.0-2.5 2.5-3.0 5-5.5 6-6.5 7-7.5 10-10.5

Main property:

1.High efficiency of grind: the proportion of zirconia ceramic bead is 1.6 times that of plain zirconia bead.Under the equal condition,it have higher grinding efficiency.

2.Good fluidity:good roundness,fine surface,The abrasion to device is lower than other medias.

3.Impulsion resistance and low abrasion:good tenacity for zirconia ceramic bead.No crazing or peel off.

4. Low using cost:Using this item can bring low comprehensive cost such as abrasion of media,electric consumption,labour cost,equipment.The quality of product improve greatly.